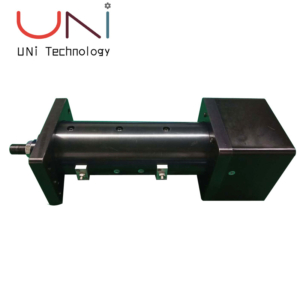

UNI High Precision Ball Screw Servo Actuator with rod eye bearing on both ends

Description:

High Precision Servo Actuator are manufactured by Shenzhen UNI Technology Co.,Ltd. It comes along with limit sensor (NPN/PNP type). Also, incremental/absolute encoder will feedback the position. PLC controllable. Besides, servo motor offers high precision control within the stroke. What’s more, speed and position are all adjustable

Custom electric cylinder specification based on requirements about stroke, speed and load.

Lead time: 3 days.

Installation: Front Flange/Rod eye bearing on both ends/Front Clevis+Rear Clevis

Electric Servo cylinder weight 12 (kg)

Electric cylinder type: In-line type or foldback type

Rotation: with anti-rotation mechanism(internal freely-rotation mechanism also available)

Gear reduction: 1:1 (Gear box will be added for some cases) Japan Shimpo,Taiwan Liming,etc

Power supply: DC 12V/24V/220V AC optional

Control way: EtherCat,CanOpen,PLC,Analog,DMX512,etc

Motor Option: Servo motor/Stepper motor/DC motor/Asynchronous motor (Panasonic, Siemens,Schneider,Moons,etc)

Technical Date

| Product | UNI-S75L400 | |

| Pitch/Screw Lead(mm) | 5 | 10 |

| Max Force(N) | 10,000 | 5000 |

| Max Stroke(mm) | 2000 | 2000 |

| Max Speed(mm/s) | 166 | 83 |

| Repeatability Accuracy(mm) | 0.02 | 0.02 |

| Ball Screw Diameter(mm) | 16 | 16 |

| Axial Backlash(mm) | 0.02-0.04 | 0.02-0.04 |

FAQ

Q1. What is the duty cycle of High Precision Servo Actuator?

A1: 100% Duty Cycle. The electric servo linear actuators or stepper motor linear actuators can work continuously.

Q2. Do you have install manual for instruction?

A2: Yes. We have instruction manual to explain maintenance and fault resolution.